|

iQ Valves offers a wide range and variety of proportional valves. Choosing the right

valve for your application is important to give you better control over the valve

and your process. |

| |

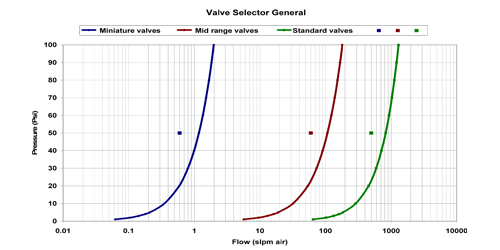

| Valve selection is based on the pressure differential the valve will see and maximum

flow expected at that pressure. Considering these parameters iQ Valves offers three

different categories of valves: |

| |

1. Miniature valves for ultra low flows вҖ“ IQ Nano

2. Mid range

valves for moderate flows вҖ“ IQ Mini, IQ Coral

3. Standard valves for high flows вҖ“ Standard PFCV |

| |

|

The following four charts will guide you in selecting a valve (based on air as the

medium). Each of them is divided into different sections by dividing lines. These

sections correspond to the category of valve in chart 1 and give the required orifice

sizes in charts 2, 3 and 4. Charts 2, 3 and 4 give the required orifice size in

Miniature (Chart #2), Midrange (Chart #3) and Standard valve (Chart #4) respectively. |

|

|

|

The following examples illustrate valve selection using the charts. |

|

|

|

Example 1: Pressure differential across the valve: 50 Psi |

|

Medium: Air |

|

Maximum required flow: 0.6 slpm |

|

|

|

To find the valve category

use chart 1. Locate a point in chart 1 with pressure and maximum required flow as

the co-ordinates (Note Chart 1 has flow in logarithmic scale). In this example the

point (with 50 psi and 0.6 slpm as co-ordinates) is in left most section on the

chart, which corresponds to Miniature valves. |

| |

|

Chart1 Chart1

|

|

|

|

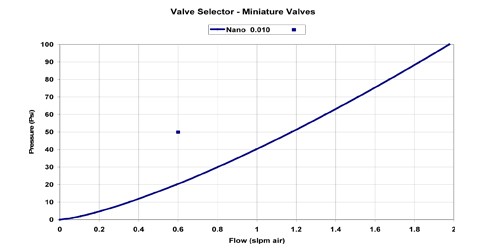

To find the required orifice

size in the Miniature valve use chart 2. The point in this chart is in the 0.010

inch orifice size section. Thus appropriate valve for this application is 0.010

inch orifice size Miniature valve. |

|

|

|

Chart2 Chart2

|

|

|

|

Example 2: Pressure differential across the valve: 50 Psi |

|

Medium:

Air |

|

Maximum

required flow: 60 slpm |

|

style="text-align:justify; padding-left:6px; padding-right:6px;"

To find the proper category

of the valve use chart 1. In this example the point (with 50 psi and 60 slpm as

co-ordinates) is in middle section on the chart, which corresponds to Midrange valve. |

|

|

|

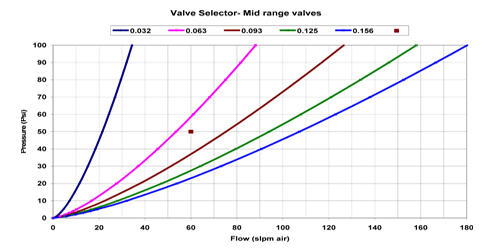

To find the required orifice

size in the Midrange valve use chart 3. The point in this chart is in the 0.093

inch orifice size section. Thus appropriate valve for this application is 0.093

inch orifice size Midrange valve. |

|

|

|

Chart3 Chart3

|

|

|

|

[For the same pressure differential of 50 psi and maximum flow requirement of 100

slpm the point will land in 0.156 orifice area, so the valve for this application

will be 0.156 orifice size Midrange valve. Another example would be for 90 psi pressure

and maximum required flow of 60 slpm the point will land in 0.062 orifice range,

so the valve for this application will be 0.062 orifice size Midrange valve.] |

|

|

|

Example 3: Pressure differential across the valve: 50 Psi |

|

Medium:

Air |

|

Maximum

required flow: 500 slpm |

|

To find the valve category

use chart 1. In this example the point (with 50 psi and 500 slpm as co-ordinates)

corresponds to Standard valve. |

|

|

|

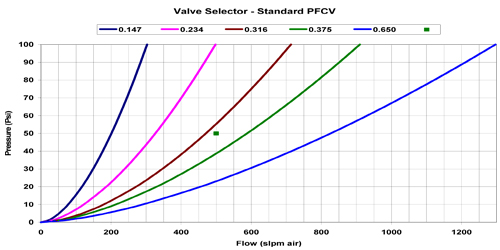

To find the required orifice

size in the standard valve use chart 4. The point in this chart is in the 0.375

inch orifice size section. Thus appropriate valve for this application is 0.375

inch orifice size Standard valve. |

|

|

|

Chart4 Chart4

|

|

|

|

[For the same pressure differential of 50 psi and maximum flow requirement of 700

slpm the point will land in 0.650 orifice area, so the valve for this application

will be 0.650 orifice size Standard valve. For 90 psi pressure and maximum required

flow of 500 slpm the point will land in 0.316 orifice area, so the valve for this

application will be 0.316 orifice size Standard valve.] |

|

|

| Proportional Valve Product Line

|

| Top |

|

|